Australian kesom oil - A new essential oil for the flavour and fragrance industry

Proceedings of the First Australian New Crops Conference held at The University of Queensland Gatton College 8 – 11 July 1996

Abstract

The trend towards natural flavour compounds is creating opportunities for the development of new essential oils. Essential oils that are sources of natural aroma chemicals will be of particular interest to the flavour and fragrance industry. Kesom oil is a potential source of natural aliphatic aldehydes and can be produced economically in North East Victoria. The oil has potential applications in flavours and fragrance compounds.

Introduction

Traditionally, the flavour and fragrance industry has taken a conservative attitude towards the acceptance of new essential oils. This is changing due to the growing demand for natural flavour compounds in Europe and the United States. There are opportunities for the introduction of new essential oils, especially those which are potential sources of natural aroma chemicals. Kesom oil is one such essential oil which should attract interest, as the oil is a potential source of natural aliphatic aldehydes.

Natural aliphatic aldehydes do exist in a number of essential oils, however only in trace or minor amounts. Extraction and isolation of these compounds is therefore very expensive. The high cost and the limited availability of natural aliphatic aldehydes hinders wide use of these materials in flavour applications, where synthetic aroma chemicals, labelled as ‘nature identical’ are preferred.

Synthetic aliphatic aldehydes are widely used in the production of flavour and fragrance compounds. n-Decanal, known in the flavour industry as aldehyde C10, is extensively used in perfume and flavour compositions. Likewise dodecanal, known as aldehyde C12 lauric is also widely used and is considered a very versatile raw material. Both materials are in abundant supply and reasonably cheap to synthesise. Aliphatic aldehydes can also be produced from natural sources like coconut and palm kernel oils, which are rich in octyl, decyl and dodecyl acids. However the processes used to convert these acids to their corresponding fatty alcohols and fatty aldehydes do not meet the definition of a natural material, as defined by the International Fragrance Association (IFRA).

The Origins and Botany of Kesom Oil

Kesom oil is obtained by steam distillation of the herb Polygonum odoratum (Lour.), a member of the family Polygonaceae. The herb has been recently renamed Persicaria odorata (Lour.) Sojak, thus establishing a more refined group of Polygonum species. Polygonum odoratum L. has green stems with tinges of red at leaf xxxx. The lance shaped leaves are deep green with a red-green crescent marked on the upper side. The herb blossoms with tiny pink flowers when the stems become woody and terminal. In southern Australia, the herb grows up to 1.5 metres in height and becomes dormant for two to three months in the winter (June-August).

Polygonum odoratum is a domesticated plant and has a long history of culinary use in south-east Asia (Burkill 1966). The herb has also been cultivated by ethnic communities in Australia for many years. Literature searches reveal very little about the origin of Polygonum odoratum in Australia, as it was most probably introduced by immigrants sometime early this century.

The existence of Polygonum odoratum is also reported in Vietnam. A comparison of the chemical analysis of the essential oil from the Australian and Vietnamese plants suggests the Vietnamese herb has a different chemo-taxonomy and therefore may be another chemotype of the same variety (Dung et al. 1995). The taxonomy of Australian Polygonum odoratum is probably closer to Polygonum minus (Huds.) found on the Malay Peninsula (Yacoob 1987). Both varieties are very similar in appearance, except that P. Odoratum has a slightly broader leaf. The chemo-taxonomy of both varieties is very similar (Yacoob 1990).

Chemical Composition and Characteristics of Kesom Oil

Kesom oil was distilled on a pilot commercial scale at the Victorian Department of Agriculture, Ovens Research Station in the North-East Region of Victoria, Australia. GC and GC-MS analyses reveal that the oil contains approximately 10% 1-alcohols (decanol-1 and dodecanol) and over 80% aliphatic aldehydes, primarily n-decanal and dodecanal. The major constituents of kesom oil are decanol-1 3.47%, dodecanol 7.15%, nonanal 0.205%, undecanal 1.40%, n-decanal 25.10%, and dodecanal 55.87%. The sesquiterpene caryophyllene, is also a constituent at 2.50%. A group of terpenes including b-cis-ocimene, b-trans-ocimene and humulene are present at under 1%. Minor traces of carboxylic acids are also present in the oil.

Kesom oil is a clear to pale yellow liquid which has a smooth but diffusive predominating aldehydic note with cool earthy and vegetable-like subsidiary notes.The odour is pungent and still very noticeable on a smelling strip after 24 hours. A 0.1% solution of kesom oil in ethanol has a sharp but rounded aldehydic note with floral, earthy and waxy suggestions in the backnotes. The oil has a specific gravity of 0.843 at 20o C. and is miscible in absolute ethanol (soluble in <1 volume of 100% ethanol, insoluble in 10% and 50% ethanol). The oil is relatively stable and is slower to polymerise than pure aliphatic aldehydes under the same conditions. This is probably because the levels of 1- alcohols and fatty aldehydes in the oil outweigh the presence of carboxylic acid traces which aid in the formation of hemiacetals in the oil (Bedoukian 1952). The oil can be safely stored at room temperature in amber glass bottles for many months and should some polymerisation occur, gentle heating of the oil will de-polymerise it.

The Production of Kesom Oil

The Ovens Valley in north-east Victoria was selected as the location to develop the crop. The research staff at the Ovens Research Station are committed to essential oil research with a good track record. Farmers in the region are eager to experiment with new crops as alternatives to tobacco production, which has been declining over the last two decades due to declining consumption. The region already has an emerging peppermint industry; approximately 15 tonnes were produced this year.

For a new essential oil to be a commercially viable proposition, high yields are necessary to enable attractive pricing to potential end users. The two major factors which most heavily influence the yield and composition of kesom oil are climatic conditions and the applied nitrogen regime during cultivation.

A mild climate appears to be the optimum situation for cultivation. The temperature of the Ovens Valley Region ranges between 11.0-32.0o C during the summer months (December-February), and 3.0- 16o C during the winter months (June-August). The days are warm with cool nights for many months of the year. The Great Dividing Range south of the valley tends to hold weather fronts to the south, thus increasing the incidence of sunshine days in the valley. The crop requires high levels of rainfall or supplemental irrigation during cultivation. Polygonum odoratum prefers partial shade during early propagation and lack of water on a hot day will tend to cause the leaves to droop. The average rainfall in the valley over the last 30 years has been 1,037 mm. In addition, irrigation water is easily accessible in the valley.

One initial concern about cultivating Polygonum odoratum in the Ovens Valley Region was the incidence of frost, an average 20.1 days per year. This concern was quickly alleviated as the crop showed itself to be hardy in withstanding frosts. Analysis of the oil after heavy periods of frost revealed that the levels of 1-alcohols and aliphatic aldehydes did not decrease as a percentage of the total oil composition to any great extent. Oil yields however were marginally lower.

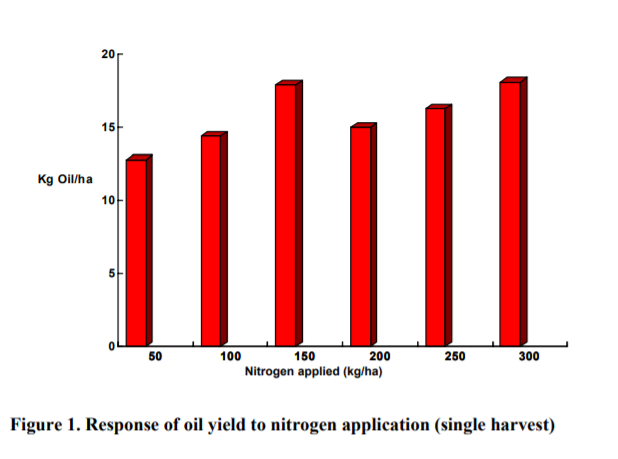

Replicated field experiments varying the application of nitrogen were undertaken to examine the effect on both the yield and oil composition. The yield and levels of the major constituents of kesom oil responded positively to nitrogen application. Figure 1 indicates the response of yield to nitrogen application.

No significant pests and diseases were observed, except for some early incidence of two spotted mite (Tetranychus viticae), although this has not been a problem in the last two years. Preferably a herbicide should be applied to the field before planting to assist in the control of early weed competition. Manual weeding is required as a supplement to the herbicide, especially in the early stages of growth. A herbicide screening and weed control program is still continuing.

The crop can be harvested two to three times a year depending on yearly weather patterns. An estimated annual yield of 36 to 56 kg/ha of kesom oil can be obtained, depending on the number of harvests. Harvest timing is not as critical as with some other essential oil crops like peppermint, as the major chemical constituents in the oil maintain consistent levels throughout the growth of the crop. Therefore, the most critical issue in determining optimum harvest time is maximising biomass to achieve high oil yields. As more is learnt about the responses of the crop to different variables and distillation practices, higher yields can be expected in the future. Not enough historical data is yet available to determine the commercial life of the crop.

Potential Industry Applications of Kesom Oil

The major advantage of kesom oil is that it is a complex of 1-alcohols and fatty aldehydes created in nature. The presence of 1-alcohols and other constituents enhance the oil’s olfactory profile. This deep and rich quality can be considered superior to any of the odour profiles of the corresponding synthetic aldehydes, currently used in the flavour and fragrance industry. In flavour and fragrance creation, kesom oil is easier to use because the material is already naturally ‘rounded off’. Thus the use of kesom oil can eliminate, or at least lessen the need for the employment of other terpenes for the purpose of balancing and adding ‘naturalness’ to flavour and fragrance compounds.

Pure aliphatic aldehydes are usually used in dilution for flavour and fragrance creation. As kesom oil is relatively stable, there are some advantages in using this material in the crude undiluted form, particularly where there is little room for solvents in flavour compositions because a high concentration is desired in a finished compound. Kesom oil is also highly effective in improving the sharpness of citrus flavours in small concentrations (ppt). Suitable applications would include citrus and fruit complexes, caramel, honey and oriental flavours.

The initial drawback to industry acceptance of kesom oil as a flavour material is that it is not currently on the GRAS list (Generally Regarded as Safe). Therefore the immediate commercial future of kesom oil will rely upon the development of its individual constituents and groups of these constituents as natural isolates. These materials are already on the GRAS list. Individual aliphatic aldehydes and 1-alcohols must be physically isolated from the crude oil to meet the IFRA definition of a natural aromatic material. Physical isolation can be achieved through low temperature fractionation to remove the low temperature boiling mono-terpenes and through further repeated fractionation to separate the individual isolates to a purity of 80% or higher. These materials will slightly differ in odour profile to their synthetic equivalents, as they will carry over traces of the parent oil.

The potential in perfumery for kesom oil is more limited. The trend to natural flavours has not corresponded in any increase in demand for natural fragrances by consumers. Even though kesom oil in small concentrations will lift and improve the citrus and floral character of fragrances very well, the material could not directly compete against existing synthetic materials already widely used in functional perfumery applications due to cost considerations. Use of Kesom oil in perfumery will be more suitable for fine fragrance applications. Kesom oil will be a good alternative to any of the single aldehydes, where creative perfumers may prefer a complex aldehydic profile for use in citrus, floral and chypre complexes.

Conclusion

The kesom project is now entering pilot stage commercial production, just three years after its formal beginning. We will find out only in the next year or so whether our assumptions about the market prove to be correct.

Gaining industry acceptance of kesom oil will require proof that the product can be produced and supplied on a consistent basis, otherwise companies within the flavour and fragrance industry will be hesitant to include this material in their palette of aroma materials. There will be a time lag between industry acceptance and use of kesom oil as perfumers and flavourists will require time, effort and imagination to realise its potential. This creates a certain degree of risk on the part of the primary producer where early production must be undertaken with some degree of speculation. Efficient and cost effective production will be a key factor in development of this new essential oil so potential application by users can be as wide as possible. The development of kesom oil as a new essential oil for use in the flavour and fragrance industry will assist in opening up possibilities for the development of other new essential oils in the future.

Acknowledgments

I wish to acknowledge the Rural Industries Research and Development Corporation for funding the research project and the Victorian Department of Agriculture for providing land and facilities. I would like to thank Mr Michael Morgan, Director of the Ovens Research Station for his support and encouragement and Mr Fred Bienvenu for his tireless research efforts.

Published in Agro Food Industry Hi-Tech, Vol. 7, No. 5, pp. 26-28, 1996

Click on subscribe so articles can be directly emailed to your inbox:

References

Bedoukian, P.Z. 1952. American Perfumer and Essential Oil Record 60:263.

Burkill, I. H. 1966. A Dictionary of the Economic Products of the Malay Peninsula,Vol. II.. (Ministry of Agriculture and Co-operatives: Kuala Lumpur), pp. 1821-1824.

Dung, N.X., Hac, L.V. and Leclercq, P.A. 1995. Journal of Essential Oil Research 7(3):339-340.

Yacoob, K. 1987. Perfumer & Flavorist 12(5):27-30. Yacoob, K. 1990. Journal of Essential Oil Research 2(4):167-172.